|

|

#31 |

|

Join Date: Mar 2022

Location: Lumberton TX

Posts: 36

|

air filters came in.

The one with the 45* elbow is the one i started out with. Slight bog down low, ran really good up top Middle one with the chrome gave good off idle response and caused it to cut out badly after about 3k but then would smooth out from 4k and up. Weird The far right, smallest cone filter. Extremely good off idle response. Every bit as impressive as fuel injection. Lowered power above 5000 rpm, causing a loss of top speed. No cutting out, surging, or bogging, just felt weak. Causing engine to cut out slightly (sounds like a misfire) just as you back off the throttle after a wide open high rpm run. refresher NIBBI PE28FL with 42 pilot, 115 main, 2 turns out on air screw, and needle in highest position. Valves both set at 0.10mm 165FMM engine. Anyone here have any ideas on which filter i should stick with, still need to correct float but im thinking small cone filter and find the jets its likes for top end.

|

|

|

|

#32 |

|

Join Date: Aug 2020

Location: Australia

Posts: 1,290

|

Myself,

I'd probably stick to the left option for increased surface area. Then maybe drop the needle a clip. the low bog might just be throttle control with to much snap. |

|

|

|

#33 |

|

Join Date: Mar 2022

Location: Lumberton TX

Posts: 36

|

The bog gets worse with any other needle position or moving up or down a pilot jet.

|

|

|

|

#34 |

|

Join Date: Mar 2022

Location: Lumberton TX

Posts: 36

|

FINALLY got this carb acting as awesome as fuel injection. NO BOG at any point in the throttle and starts cold in an air conditioned garage with no help, choke anything, and even cold runs flawless.

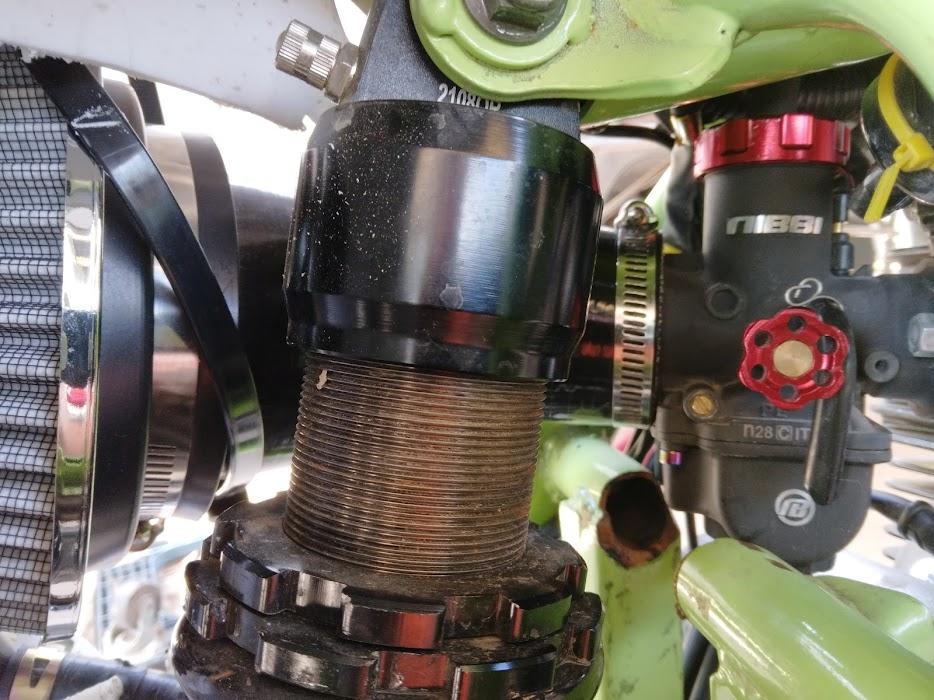

3 different pod filters, 3 different results. None were perfect. Then i got to thinking about some of the hot rods i've built and had an "ah ha" moment. It needed a velocity stack. Yet it needs a filter. So the answer was a 2"-3" 45* silicone turbo boot, and a 3" ID spectre air filter. This kills the turbulence in the carb, and creates the "constant velocity" the carb requires. Something a normal pod filter alone cannot do. The jetting changed drastically with this set up as well. With the best running pod filter (ran the same with NO filter) it used a 42 pilot and a 115 main with the needle in the # 5 position. float set dead on at 18mm. This Gave me very good throttle response and awesome power to get the front end off the ground with my 15t-40t sprocket set. The down side is i lost all power above 5,000 rpm killing my top end. With this new set up, jetted at 42 pilot, 145 main (anything lower than 140 and there is bog from 3/4 throttle to wide open), and needle still in the #5 position, float still set dead on at 18mm, I kept the awesome throttle response and can now rev instantly to 10,000 rpm. Way to high, in neutral it revs like a 2 stroke now. Now i can hit 80mph with the wind at my back at 8500 rpm. Again, revved to high but it will do it. The vibrations above 60 mph are annoying, above 65mph the vibration is awful but seems to smooth out after 70. Harmonics maybe???? Anyway it now hangs neck and neck with my friends Honda 300L. Except i have a better 1st gear for wheelies and trail riding. His first gear sucks. The very over sized pod filter actually fits under the plastics. .

|

|

|

|

#35 |

|

Join Date: Apr 2017

Location: Omaha, NE

Posts: 8,019

|

What it needed was a length if intake before the inlet to reduce turbulence before the inlet and help it gain velocity across the jets. Nice setup, puts everything out of the way very effectively.

__________________

Hawk Information and Resource guide: http://www.chinariders.net/showthread.php?t=20331 2018 Hawk 250 - Full Mod list here. http://www.chinariders.net/showpost....62&postcount=1 2024 Royal Enfield Shotgun 650 https://chinariders.net/showthread.php?t=34124 |

|

|

|

#36 | |

|

Join Date: Oct 2021

Location: Lumberton TX (Southeast TX)

Posts: 110

|

Another Lumberton Texas Chonda Guy

Quote:

The only mods I've done so far is 17 tooth on the front. I still have the stock 46 tooth on the rear but I did put some Honda sprocket studs on there in the high quality o-ring chain for peace of mind. I think I'm keeping the stock air box but I have carved a lot more opening on it for more air. I've also put a sleeve in the air hose to keep it from collapsing in this hot Texas sun. I don't know what part of Lumberton Texas you're in but the part of Lumberton Texas that I'm in gets awful hot and swampy in the summertime (snicker ol). Other minor modifications include: -A 12 pin racing CDI box -A Nibbi performance ignition coil -MSD 3311 Spark Plug Wire Boot and Terminal -NGK DPR8EIX-9 Iridium IX Spark Plug I've also put some zerts here and there so I can keep the swing arm in the steering stem greased. I'm am looking to upgrade to upgrade the exhaust, get a Big Bore Kit and ported head in the next month or two (or 3). Please answer just a few questions for me while keeping in mind I've got the stock air box slightly modified to take in more air and the stock exhaust, un-gutted, with no modifications. I'm started the PE28FL with the stock 1.5 turns out on the air screw, 115 main,40 pilot & the needle set in the middle at 3. It barely started and would die when I would give it any throttle at all. I turned the air screw in to where it was about a half a turn out and it seemed to be running good. I took it for real short test run and it seemed to be running great until I gunned it real hard in 4th gear, from about half to full throttle & that would cause it to bog a bit. Questions: 1. Shouldn't the air screw be turned out at least one full turn? 2. Where's your air screw set at? 3. Does that mean I should go down to 4 on the needle? 3. You're saying you have the float set at 18 mm. Please excuse my ignorance but I don't see anything in the instructions about the float set. Is there another name for the float set or can you link me somewhere that'll tell me about the float set? Thanks for taking time to read this. |

|

|

|

|

#37 | |

|

Join Date: Oct 2021

Location: Lumberton TX (Southeast TX)

Posts: 110

|

Another Lumberton Texas Chonda Guy

Quote:

The only mods I've done so far is 17 tooth on the front. I still have the stock 46 tooth on the rear but I did put some Honda sprocket studs on there in the high quality o-ring chain for peace of mind. I think I'm keeping the stock air box but I have carved a lot more opening on it for more air. I've also put a sleeve in the air hose to keep it from collapsing in this hot Texas sun. I don't know what part of Lumberton Texas you're in but the part of Lumberton Texas that I'm in gets awful hot and swampy in the summertime (snicker ol). Other minor modifications include: -A 12 pin racing CDI box -A Nibbi performance ignition coil -MSD 3311 Spark Plug Wire Boot and Terminal -NGK DPR8EIX-9 Iridium IX Spark Plug I've also put some zerts here and there so I can keep the swing arm in the steering stem greased. I'm am looking to upgrade to upgrade the exhaust, get a Big Bore Kit and ported head in the next month or two (or 3). Please answer just a few questions for me while keeping in mind I've got the stock air box slightly modified to take in more air and the stock exhaust, un-gutted, with no modifications. I'm started the PE28FL with the stock 1.5 turns out on the air screw, 115 main,40 pilot & the needle set in the middle at 3. It barely started and would die when I would give it any throttle at all. I turned the air screw in to where it was about a half a turn out and it seemed to be running good. I took it for real short test run and it seemed to be running great until I gunned it real hard in 4th gear, from about half to full throttle & that would cause it to bog a bit. Questions: 1. Shouldn't the air screw be turned out at least one full turn? 2. Where's your air screw set at? 3. Does that mean I should go down to 4 on the needle? 3. You're saying you have the float set at 18 mm. Please excuse my ignorance but I don't see anything in the instructions about the float set. Is there another name for the float set or can you link me somewhere that'll tell me about the float set? Thanks for taking time to read this. |

|

|

|

|

#38 |

|

Join Date: Mar 2022

Location: Lumberton TX

Posts: 36

|

I sent you a private message with my phone number. It is much easier to explain than it is to try to type all that out

|

|

|

|

|

|

|

|